Value Added Solution

INVENTORY MANAGEMENT

Just-in time Delivery, Warehousing, EDI

TECHNICAL ASSISTANCE

To listen and understand your specific requirements and provide Technical Support and Consulting Services.

GRAPHIC AND STRUCTURAL DESIGN

Conceptualization, brainstorming, prototype development, sketching, rendering and mockups.

PACKAGE PERFORMANCE TESTING

Professional testing services, creative problem solving, material evaluation, performance testing

PACKAGE VALUE ANALYSIS

Review, analysis and action plan designed to drive out system costs related to packaging (in both the product and manufacturing process).

PACKAGING SOLUTIONS

Optimize your entire supply chain including materials management, rightsizing, and sustainability controls, to protect your brand’s reputation and deliver your product .

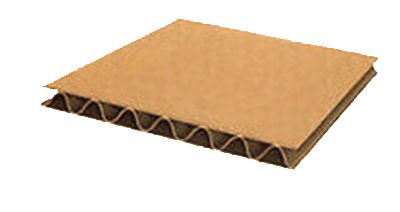

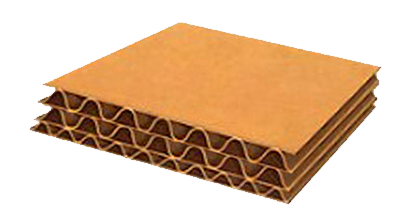

FLUTE PROFILE

Architects discovered long ago that an arch with the proper curve is the strongest way to span a given space. Corrugated sheets have evolved with this basic principal in mind. The fluted medium is bonded to the liners with a starch adhesive. Once bonded the combined board resists bending. The flutes provide cushioning when pressure is applied from the sides and when placed on end they form rigid columns capable of supporting a great deal of weight.

The most commonly used flutes are C and B flute. Others include A, E, and F flute. Specialty micro-flutes have been recently created to form specialized grades capable of competing in the boxboard market. Generally, larger flutes offer greater vertical compression strength and cushioning. Smaller flutes offer printability advantages as well as structural advantages for retail packaging.

STANDARD CORRUGATED FLUTES

Flute Designation

Flutes per Linear Metre

Flute Thickness (mm)

Flute Cross Section

B Flute

154±10

3.18

C Flute

128±10

3.97

ONGOING CERTIFICATION